NEWS

NEWS

How does PCB board conduct heat most effectively?

PCB (Printed Circuit Board), is a support for electronic components and a carrier for electrical connection of the electronic components. After the electronic equipment adopts PCB, due to the consistency of similar printed boards, manual wiring errors are avoided, and automatic insertion or placement of electronic components, automatic soldering, and automatic detection can be realized, which ensures the quality of electronic equipment. It improves production efficiency, reduces costs, and facilitates maintenance.

As PCB boards continue to develop in the direction of high precision, high density and high reliability, they can continue to shrink in size and cost while achieving improved performance, making PCBs still maintain a strong vitality in the future development of electronic equipment. In the future, it will continue to develop towards high density, high precision, fine aperture, fine wire, fine pitch, high reliability, multi-layer, high-speed transmission, light weight and thinness.

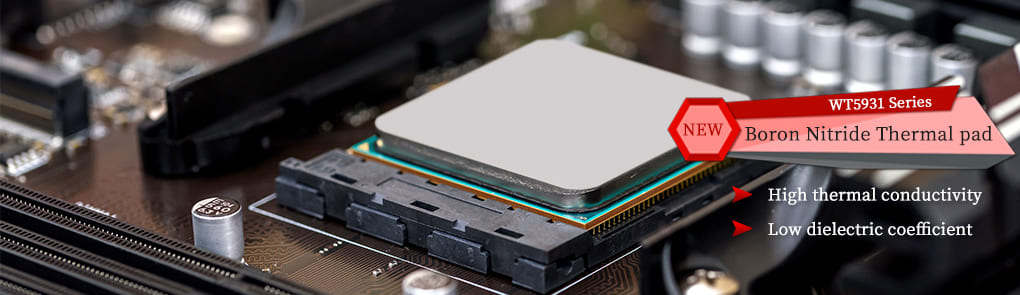

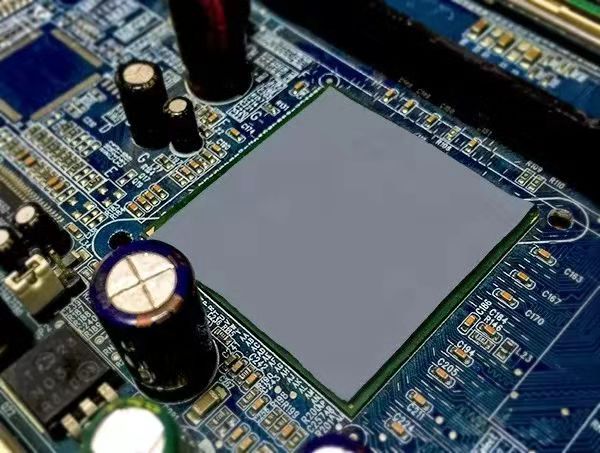

PCB boards are widely used in electronic equipment. The heat generated by electronic equipment during operation will cause the internal temperature to rise rapidly. If the heat is not released in time, the equipment will continue to heat up and the device will fail due to overheating. The reliability of the electronic equipment will decline. Therefore, when there are many heating devices, a large heat sink is generally used. A special heat sink is customized according to the position and height of the heating device on the PCB board, or different height positions are cut out on a large flat plate heat sink. The whole is buckled on the component surface, and contacts with each component for heat dissipation. However, due to the difference in the height of the components during assembly and welding, the heat dissipation effect is not ideal. Generally, a soft thermal conductive silicon pad is required to improve the heat dissipation and heat dissipation effect on the component interface.

Recommended models

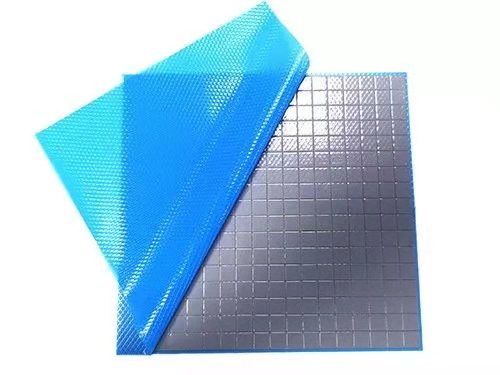

WT5912 series thermal pad

Model: WT5912-H20-55; WT5912-H25-40

Waermtimo researched and developed TIM's new high-strength thermal pad, which is a thermal conductive sheet with high mechanical strength, elongation rate> 300%, high toughness, thermal conduction and shock absorption at the same time, and can be reworked many times. It can not be fractured and can tightly integrate irregular or complex surfaces, has excellent interface filling and can be used repeatedly. Temperature resistance range -50 ~ 200 ℃, applicable to a wide range of power equipment, automotive electronics, communication equipment, network terminals, storage devices, handheld, wearable, mobile terminal products between the internal chip and the radiator. This series thermal pads can be used to solve the problem of heat conduction and heat dissipation. At the same time, it can also be applied to the housing of some electronic products, which has the functions of heat dissipation, insulation, dust resistance and water resistance.

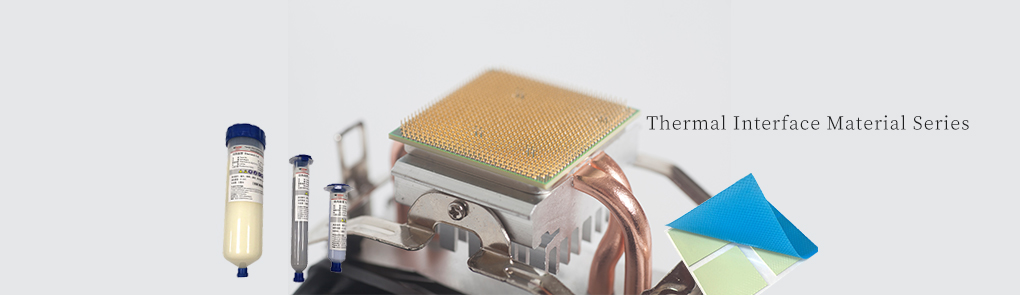

WT5902 series thermal pad

Model: WT5902-D40-40; WT5902-D45-40

Thermal conductivity range:

4W, 5W, 6W, 7W, 8W

WT5902 series thermal pads can solve the problem of tolerance changes when design the produc’s structure, and can be reused. They are excellent vertical heat transfer material between the heat source (CPU or electronic chipset) and the heat sink. Have good insulation and mechanical properties, can tightly integrate irregular or complex surfaces, easy to use and easy to remove. It is widely used in power supply equipment, automotive electronics, communication equipment, network terminals, storage devices, consumer electronics and other fields.

For more product information, welcome you

Visit the official website: www.waermtimo.com

Email: [email protected]

Cel: +86 15222362618