NEWS

NEWS

The faster the dispensing speed, the better of the thermal gel?

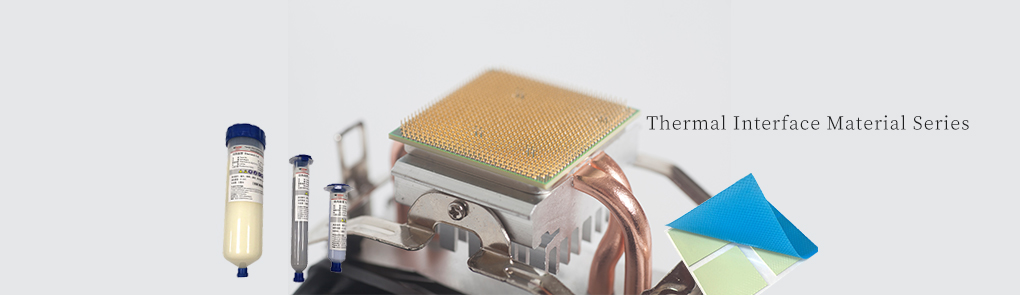

The degree of mechanical automation is getting higher and higher, especially for electronic products. The update iteration speed is getting faster and faster, which puts forward higher requirements for product production speed. In the changing market process, Waermtimo has launched the WT5921 series of thermal gel suitable for automated dispensing of machinery and equipment.

Since it is machine automated dispensing, in order to pursue faster production efficiency, many people think that the faster the dispensing speed, the better of the thermal gel. So is it actually the case?

Many people who have just come into contact with thermal gel are more inclined to pursue the fluidity of thermal gel from the perspective of production efficiency, but ignore the most important role of the product itself-to solve the problem of thermal conductivity and heat dissipation of the product. The flow rate of the thermal gel is important, but in practice, the faster the flow rate, the worse the thermal conductivity effect, and the reliability of the product is greatly reduced. This is because thermal gel with high flow rates often have high silicone oil content and less thermally conductive filler of powder body.

So how can we balance the relationship between thermal gel flow rate and thermal conductivity?

In the process of continuously listening to customer feedback and applications, Waermtimo started to solve this problem from the following aspects:

1. The thermal gel flow rate is controlled within a certain value range, which can achieve the best balance between thermal conductivity and equipment operability;

2. The flow rate of the thermal gel is controlled within a certain value range, which can ensure that the silicone oil precipitation rate is minimized and avoid affecting the performance of the product due to the precipitation of silicone oil;

3. WT5921 series thermal gel adopts special materials and processes. Under normal working conditions, it does not dry or powder, which maximizes heat transfer and achieves the best thermal conductivity.

4. The WT5921 series thermal gels with different thermal conductivity such as 1.0w, 2.0w, 2.5w, 3.0w, 3.5w, etc., which can meet the thermal conductivity requirements of different products.

For more product information, welcome you

Visit the official website: www.waermtimo.com

Email: customerservice@waermtimo.com