Contact us

NEWS

How can LED projectors dissipate heat more effectively?

LED (Light Emitting Diode) technology applied in the field of display and lighting has been very mature. With the advancement of technology, this technology has been applied to projectors, and more experienced manufacturers have combined this technology with DLP (Digital Light Processing) The perfect combination of technology makes the LED projector portable and compact, and because of its low power consumption and heat generation, it is widely used in life and personal business.

The optical element is the core part of the imaging display in the LED projector. The main components that are easy to generate heat and are affected by the heat are the light bulb and the LCD panel and the nearby optical devices. The projection imaging technology of the projector requires a high light source output. Due to the small size of the device and the concentrated heat, 75% of the projector's power is dissipated in a very small space. If the temperature is too high, the devitrification of the quartz on the inner wall of the LED bulb will occur, which will cause white spots, cause the local area temperature to rise abnormally, and further expand, and then the brightness will rapidly decay. For other optical components, once the temperature exceeds the range, the optical components will be damaged. Therefore, the effectiveness of heat dissipation will directly affect the life of the LED projector.

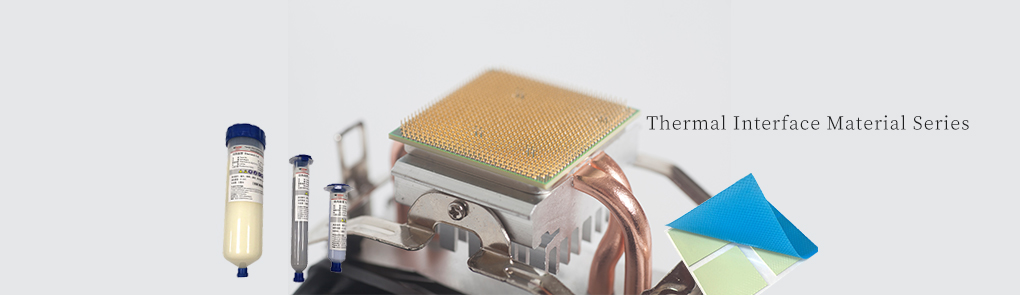

How to quickly transfer the heat generated by the LED projector to the air? This requires a reasonable thermal design. General LED projectors are not only designed with large-area heat dissipation holes in the housing, but also equipped with pure copper heat sinks for efficient heat dissipation. However, this does not maximize the heat dissipation effect, because the heat sink and the chip cannot be perfectly bonded, and the air in the gap between the two is a poor conductor of heat. Therefore, a thermally conductive silicon film is required to achieve heat conduction.

Solution

WT5912 series thermal pad

Model: WT5912-H20-55; WT5912-H25-40

Waermtimo researched and developed TIM's new high-strength thermal pad, which is a thermal conductive sheet with high mechanical strength, elongation rate> 300%, high toughness, thermal shock and effective damping at the same time, and can be reworked many times. Continuously, it can tightly integrate irregular or complex surfaces, has excellent interface filling and can be used repeatedly. Temperature resistance range -50 ~ 200 ℃, applicable to a wide range of power equipment, automotive electronics, communication equipment, network terminals, storage devices, handheld, wearable, mobile terminal products between the internal chip and the radiator, This type of thermal pad can be used to solve the problem of heat conduction and heat dissipation. At the same time, it can also be applied to the housing of some electronic products, which has the functions of heat dissipation, insulation, dust resistance and water resistance.

WT5902 series thermal pad

Model: WT5902-D40-40; WT5902-D45-40

Thermal conductivity range: 4W, 5W, 6W, 7W, 8W

WT5902 series thermal pads can solve the problem of tolerance changes of product structure design, and can be reused. It is a good vertical heat transfer material between the heat source (CPU or electronic chipset) and the heat sink. Has good insulation and mechanical properties, can tightly integrate irregular or complex surfaces, easy to use and easy to remove. It is widely used in power supply equipment, automotive electronics, communication equipment, network terminals, storage devices, consumer electronics and other fields.

You can get it through contact: customerservice@waermtimo.com