Contact us

NEWS

Why the thermal silica pad is the leading material for electronic product cooling?

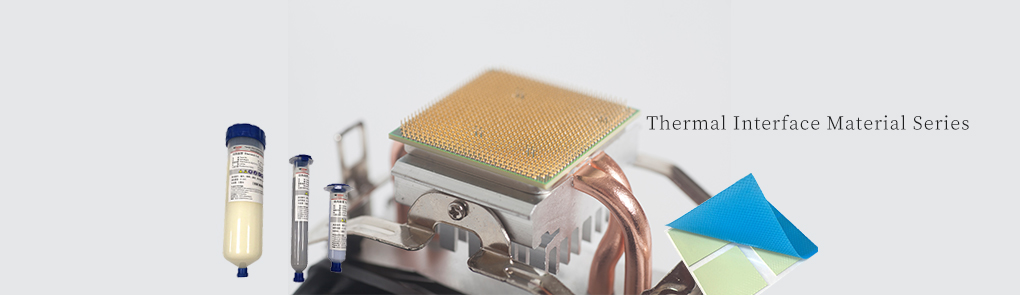

With the rapid development of science and technology, the advanced high-tech electronic products in the market are constantly updated, and are deeply loved by consumers. Any accessory in the installation of electronic products is particularly important, including some thermal materials. And any electronic product generates a large amount of heat during operation. In order to extend the service life of the electric products and provide a good user experience, internal heat dissipation and heat conduction problems are inevitable. The thermal pad solves this problem and is a widely used heat-dissipating and heat-conductive material.

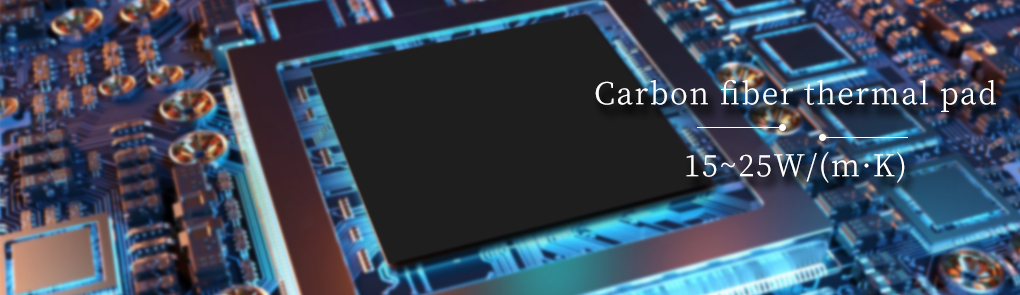

The thermal conductive silicone pad is specially used to fill the gap to realize the connection between the heat source and the heat dissipating component, transfering the heat to achieve the heat dissipating effect. The application of thermal pad not only solves the problem of heat dissipation, but also has the effect of insulation and shock absorption between components. It is the best choice for design and development of ultra-thin electronic products.

Many people will doubt that the thermal conductivity of metal products is much higher than that of thermal silica pad. Why not use metal directly for heat conduction?

In simple terms, it is because

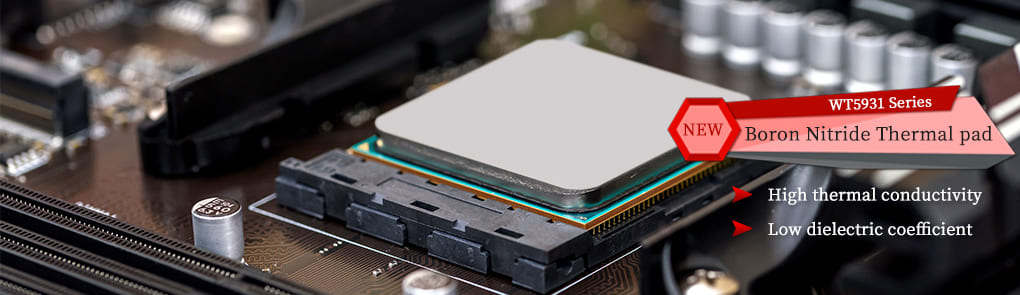

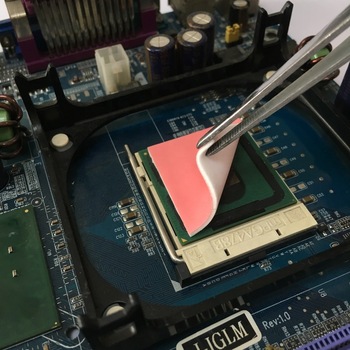

1, CPU and heatsink pad is the most common heat sink combination, if the use of metal, unless the heat sink and CPU are integrated, there must be a gap. As long as there is gap, it’s basically difficult to achieve the heat conduction effect of any kind of heat conduction scheme. But the thermal conductivity silicone material has adjustable hardness, and the compression performance is excellent. It can fill in any gap to optimize the thermal conductivity. The thermal pad has a natural micro-stickiness and is very convenient to handle.

2. The thermal pad can effectively reduce the contact thermal resistance generated between the heat source interface and the contact surface of the heatsink components, improving the performance of the electronic device. Therefore, in the process of designing the heat dissipation scheme of the electronic product, the use of the thermal pad as the heat conduction medium can make the contact surface of the heat source and the heat dissipation terminal or the outer casing more fully, and the performance is optimized.

Fast contact: customerservice@waermtimo.com